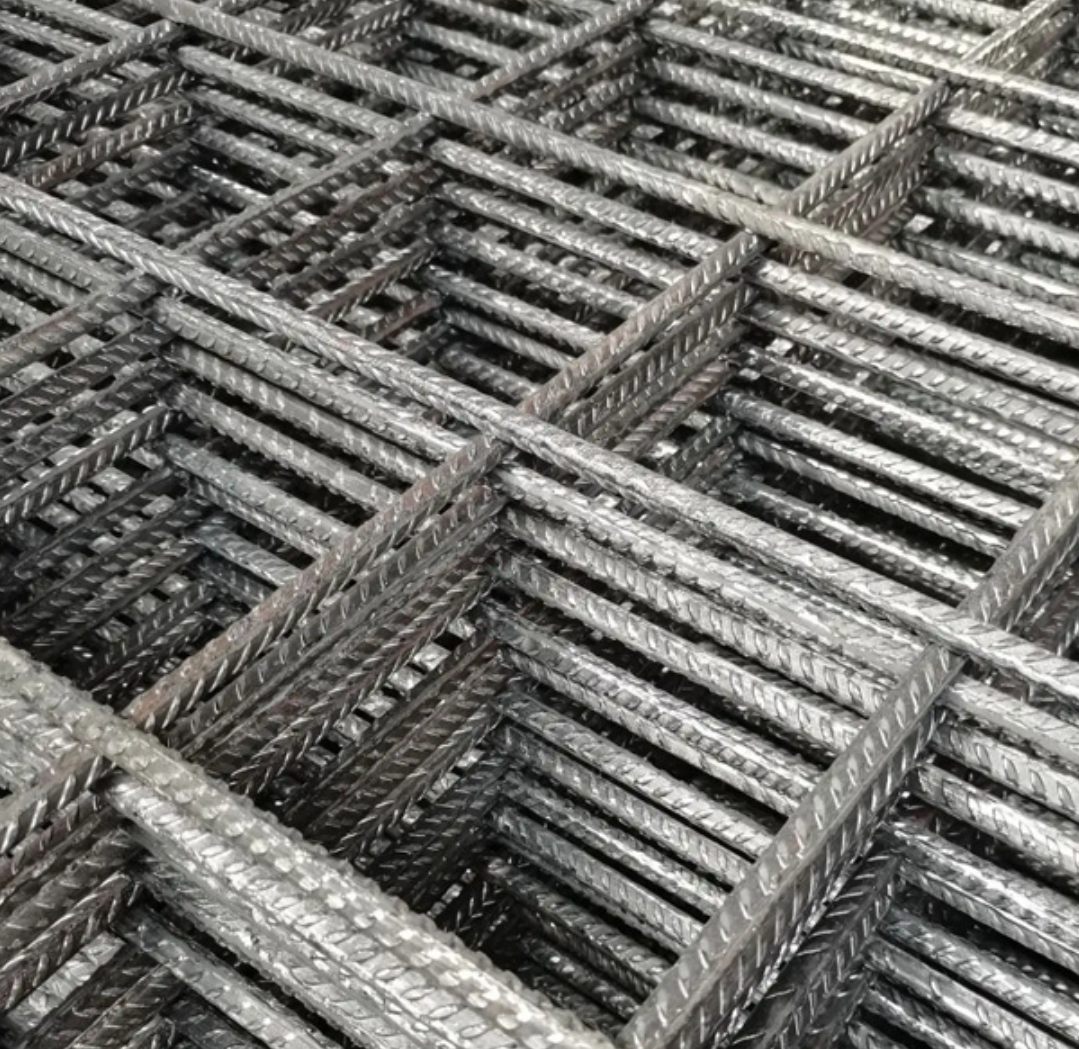

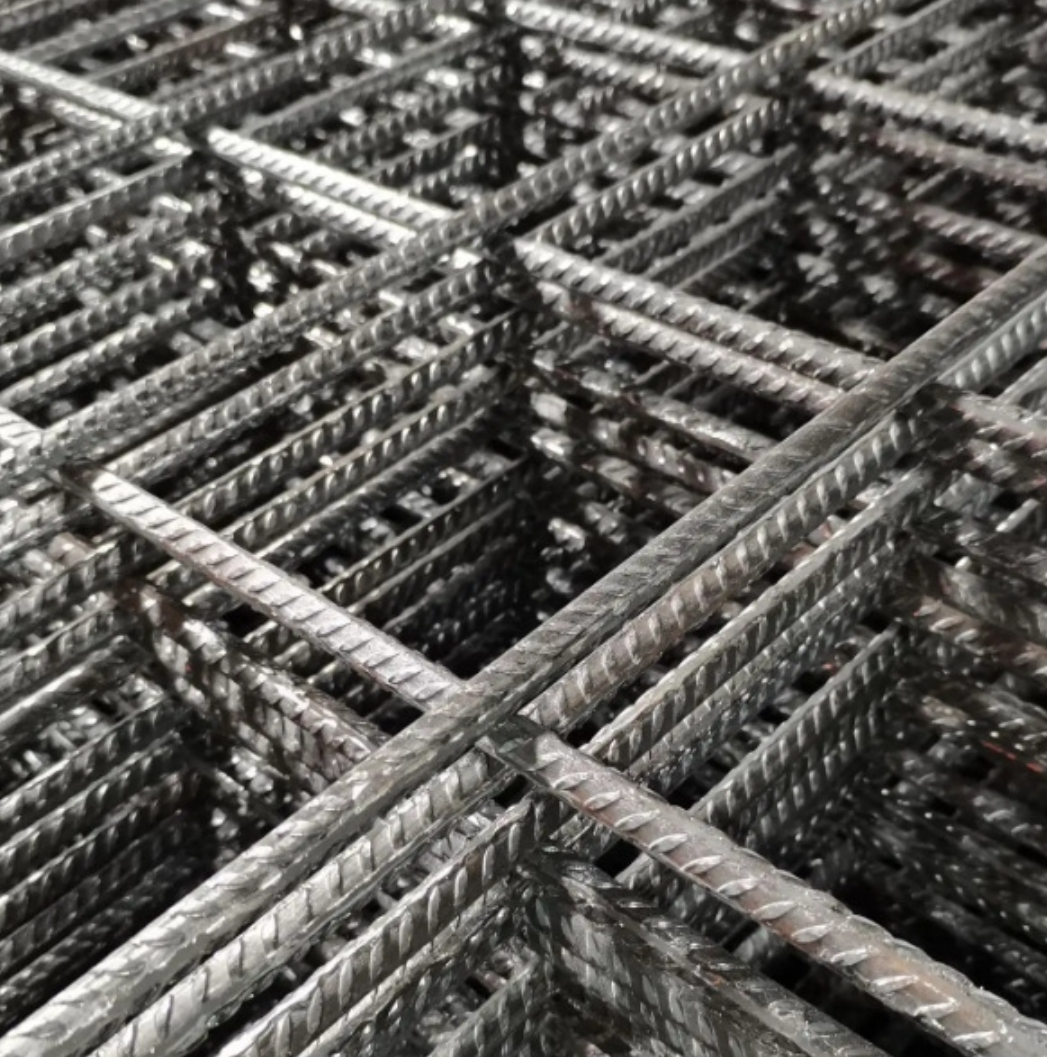

Rebar welded Wire Mesh Panel

Rebar welded Wire Mesh Panel

Material: Rebar welded Wire Mesh

Certificate: SGS,ISO9001,IS014001,IS045001

Brand: SenZhe Mesh

Support: Standard products, customization

Origin: China

Product introduction

Steel wire mesh is a kind of steel wire mesh welded by automatic electric welding equipment, which is widely used in buildings, Bridges, tunnels, roads and other concrete structure projects. Its strong structure, high strength, convenient construction, especially suitable for large area concrete reinforcement occasions. The steel welding mesh not only improves the overall strength of the building structure, but also effectively prevents the generation and development of cracks. The following are detailed introductions from the aspects of product material, structural design, application scenarios, installation and maintenance, and product advantages.

Material and characteristics

Steel welding mesh is mainly made of cold-rolled ribbed steel bars, hot-rolled ribbed steel bars or smooth round steel bars, these steel bars have high strength and excellent tensile properties, in line with national and international building codes. The diameter of the steel bar is usually 4mm to 12mm, which is selected according to the engineering needs. The steel mesh adopts the advanced electric welding technology to cross weld the vertical and horizontal steel bars to form the mesh form with high strength and stable structure. Due to the strong welding point, the steel welding mesh has strong integrity and can effectively resist the action of tensile force and shear force.

Structural design

The steel bar welding mesh is staggered and welded together by automatic equipment at a certain distance. Usually, the spacing of vertical and horizontal steel bars is 100mm to 300mm. The diameter of steel bars and the spacing of mesh holes can be customized according to the specific needs of the project. The steel bars at the weld points are maintained with a high strength connection, ensuring that the mesh does not deform or loosen during construction and after the concrete is poured. The whole structure design of steel bar welding mesh improves the durability and crack resistance of concrete engineering, and is an ideal choice for large area building foundation reinforcement.

Application scenario

Steel welding mesh is widely used in a variety of construction and infrastructure fields, especially in large areas of concrete structures play a key role in strengthening. Its specific application scenarios include:

Construction engineering: Used for reinforcing concrete components such as floors, walls, columns and foundations, effectively improving the bearing capacity and seismic performance of buildings.

Bridge engineering: the bridge deck, pier, abutment and other parts of the bridge are often reinforced with steel welding mesh to ensure its structural stability and service life.

Tunnel engineering: The steel mesh in the tunnel is used to support the concrete lining to enhance the compression and durability of the tunnel.

Roads and airport runways: Concrete pavement used for roads and airport runways can prevent cracks and extend the service life of the pavement.

Water conservancy and protection engineering: In DAMS, levees, slope protection and other water conservancy facilities, steel welding mesh provides additional structural strength to resist water erosion and natural disasters.

Installation and maintenance

The installation of steel bar welding mesh is simple and fast, and is usually laid on the construction site according to the requirements of the drawings and fixed with other steel structures. Because the mesh size and bar spacing of the electric welding mesh are pre-welded, the binding work of the construction site is reduced, and the construction efficiency is significantly improved. In addition, the construction quality of the steel welding mesh is more controllable, the welding point is firm, and the loosening and displacement problems that may be caused by the traditional binding steel mesh are avoided.

In terms of maintenance, steel welding mesh is usually buried in concrete and is not directly exposed to the external environment, so there is basically no need for additional maintenance work after the completion of the project. For exposed parts, simple anti-corrosion treatment can be carried out if necessary to ensure long-term service life and structural stability.

Product advantage

High strength, stable structure: steel welding mesh through the automatic welding process, the solder joint is firm, the overall strength of the mesh is high, can withstand greater external force, suitable for a variety of large concrete structures.

Improve construction efficiency: Compared with traditional binding steel bars, electric welding mesh can be quickly installed, reducing the time and cost of manual binding on site, and significantly improving the construction progress.

Prevent concrete cracking: The steel mesh is evenly distributed in the concrete, which can effectively absorb the tensile stress of the external load and prevent the crack formation and expansion of the concrete members.

Save materials and reduce costs: The steel welding mesh adopts accurate design and processing methods to reduce material waste, and at the same time, due to its good mechanical performance, it reduces the requirements for concrete thickness and saves construction costs.

Strong applicability: steel welding mesh is suitable for a variety of complex building structures and terrain, and can be flexibly customized according to engineering needs to ensure the best reinforcement effect.

Environmental protection: Steel welding mesh is made of high-strength, recyclable steel, which not only reduces the resource consumption of the project, but also meets the requirements of environmental protection.

Looking for the best Wire Mesh?

Schedule a Consultation

Get in touch with us now and book your appointment or get a free consultation for the issue you are facing.

Email:Leoni@senzhemesh.com

Phone/Whtsapp: +86 15933183030

Send Us A Message