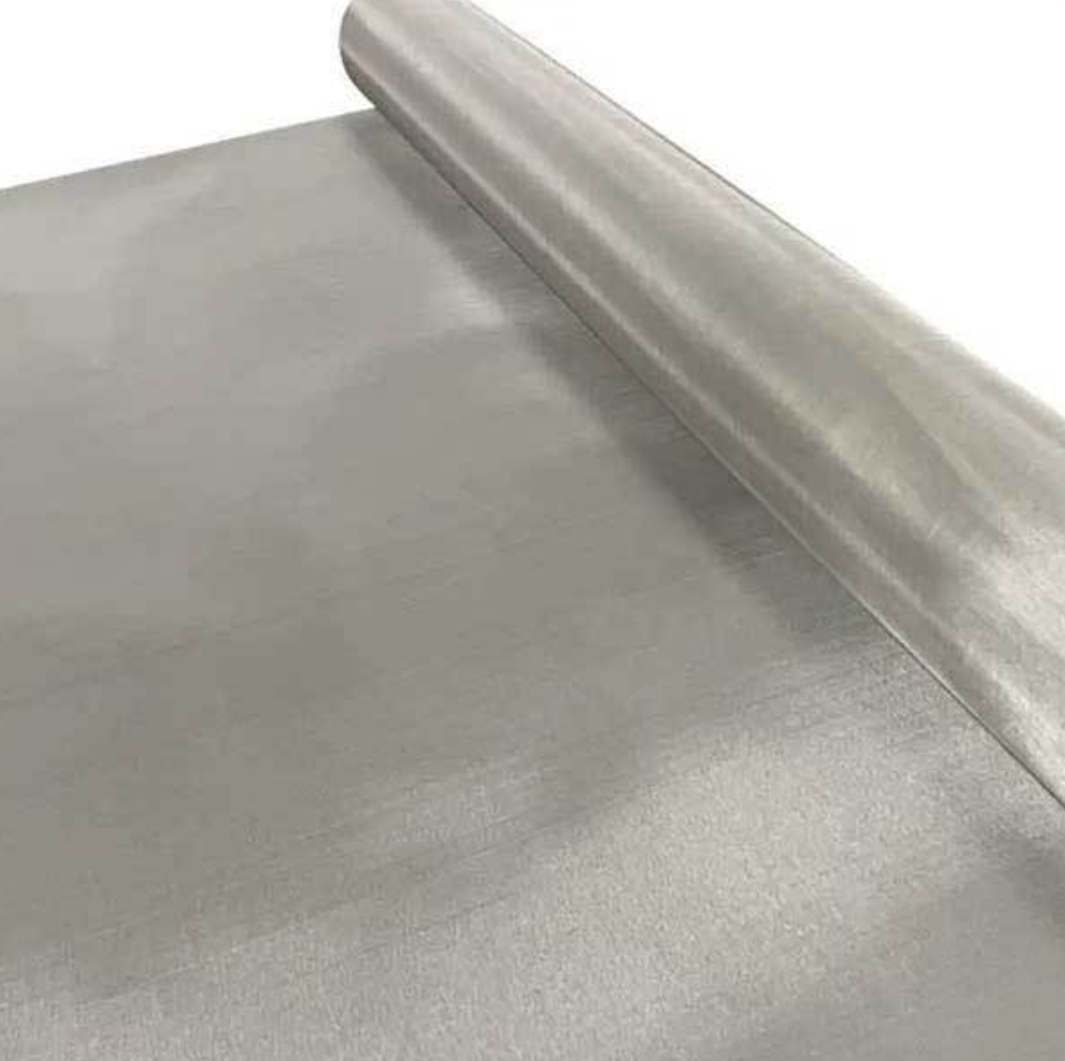

Stainless Steel Woven Mesh

Stainless Steel Woven Mesh

Material for Stainless Steel Wire Mesh and Woven Wire Cloth : 304, 304L, 316, 316L, 321, 430, 317L, 904L, etc.

Property of Stainless Steel Woven Wire Mesh and Wire Cloth: Acid resisting, alkali resisting, heat resisting, durable

Stainless Steel Woven Wire Mesh and Wire Cloth Application: Sifting and filtering in acid and alkali conditions. Slurry net in petroleum, sifting and screening mesh in chemical and chemical fiber industry, acid washing mesh in electric plating industry.

Wire diameter: 0.02–2 mm

Mesh count: 1–635 mesh

Product introduction

Stainless steel woven mesh is a kind of stainless steel wire through precision weaving process made of metal mesh products, with its excellent corrosion resistance, high temperature resistance, mechanical strength and fine mesh structure, widely used in industry, construction, filtration, screening and other fields. Its production process is flexible and diverse, and can be woven plain, twill, bamboo and other ways according to different needs to meet the requirements of different occasions.

First, the main characteristics of stainless steel woven mesh

Excellent corrosion resistance

Stainless steel woven mesh is made of high-quality stainless steel wire, usually 304, 316, 316L and other stainless steel materials, with excellent corrosion resistance. It can maintain stable structure and performance in acidic, alkaline, humid, corrosive environment, no rust, no deformation, suitable for chemical, petroleum, pharmaceutical and other need corrosion resistant materials occasions.

High temperature resistance and oxidation resistance

Stainless steel braided mesh has the characteristics of high temperature resistance, can maintain its mechanical strength and stability in high temperature environment, suitable for high temperature heating furnace, heat treatment equipment, oven and other occasions. At the same time, stainless steel material has good oxidation resistance, can resist oxidation at high temperature, extend the service life of the product.

A variety of weaving methods

According to different use needs, stainless steel woven mesh can be used in a variety of weaving methods, including plain weave weave, twill weave, bamboo weave, etc. :

Plain weave: simple structure, uniform aperture, suitable for ordinary screening and filtration.

Twill weave: Tighter weave for high precision filtration.

Bamboo knot weaving: Unique appearance design, enhances the mechanical strength of the net, suitable for heavy screening.

High strength and flexibility

While maintaining high strength, stainless steel woven mesh has certain flexibility, can withstand external impact and tensile, and is not easy to deformation or fracture. This makes it more durable and stable in mechanical operations such as screening and filtration.

Second, the application field of stainless steel woven mesh

Industrial filtration and screening

Stainless steel woven mesh is widely used in filtration and screening equipment in chemical, petroleum, medicine, food and other industries. With its corrosion resistance and high-precision aperture control, it can effectively filter impurity particles in liquids and gases to ensure the purity of the medium and product quality. In the petrochemical industry, stainless steel woven mesh is commonly used as a filter material in dewaxing and degassing equipment.

Architecture and decoration

Stainless steel woven mesh is also widely used in the field of architecture and decoration because of its smooth surface and uniform mesh structure. It can be used for building exterior walls, guardrail, stair protection board, curtain wall and other decorative materials, which not only provides safety protection function, but also adds modern sense and aesthetics. At the same time, the stainless steel material makes it durable and easy to clean, suitable for indoor and outdoor decoration.

Mechanical protection and safety barriers

In machinery manufacturing and equipment production, stainless steel woven nets are commonly used as shields and isolation nets to protect the safety of machinery and equipment and operators. Its high strength and impact resistance make it able to effectively block the splash or debris generated during mechanical operation and improve the safety of the production environment.

Electronic and communication equipment

The fine mesh and conductive properties of stainless steel braided mesh make it used as a shielding net and heat dissipation net in electronic and communication equipment to play the role of electromagnetic shielding and heat dissipation. It can prevent electromagnetic interference, ensure the normal operation of electronic equipment, and improve the heat dissipation efficiency of the equipment through the ventilation hole to extend its service life.

Agriculture and food processing

In the agriculture and food industry, stainless steel woven nets are used for screening, filtration, drying and other processes, such as grain screening, flour filtration, food drying and so on. Its non-toxic and harmless, not easy to rust characteristics, to ensure food safety and processing equipment hygiene.

Third, the advantages of stainless steel woven mesh

Easy to clean and maintain

The surface of stainless steel braided mesh is smooth, the aperture is uniform, it is not easy to accumulate impurities, and it is very convenient to clean. For applications that require frequent cleaning and disinfection, such as food processing, pharmaceutical production, etc., stainless steel woven mesh is undoubtedly the best choice.

Durability and long life

Stainless steel woven mesh has excellent durability and can maintain its physical properties and structural integrity even in harsh environments. Compared to other metal or plastic mesh, stainless steel woven mesh has a longer service life, reducing replacement and maintenance costs.

Stability and reliability

Stainless steel woven mesh in the production process through strict quality control to ensure that each piece of mesh aperture, weaving mode and size are up to standard. This high stability and reliability allows it to play a key role in precision screening, filtration and mechanical protection.

Looking for the best Wire Mesh?

Schedule a Consultation

Get in touch with us now and book your appointment or get a free consultation for the issue you are facing.

Email:[email protected]

Phone/Whtsapp: +86 15933183030

Send Us A Message