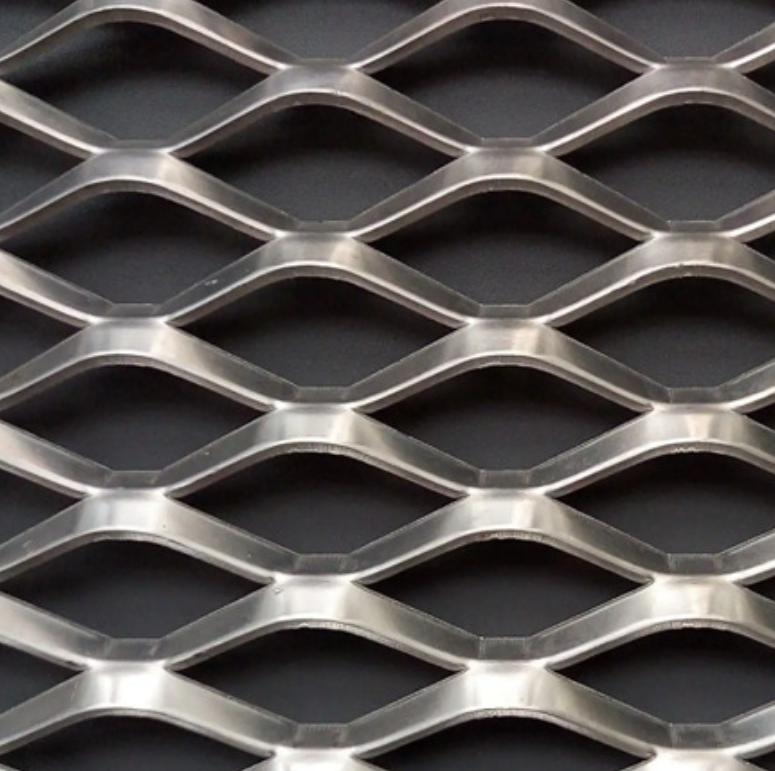

Mild Steel Expanded Metal

Mild Steel Expanded Metal

Material: Mild Steel Expanded Metal

Certificate: SGS,ISO9001,IS014001,IS045001

Brand: SenZhe Mesh

Support: Standard products, customization

Origin: China

Product introduction

Steel plate mesh is a kind of metal product with mesh structure produced by mechanical stamping, shearing and drawing process of metal plate. Its porous structure is uniform and diverse in shape, usually diamond, hexagon, square and so on. Steel mesh is widely used in construction, decoration, security protection, equipment platform and other fields, because of its excellent strength and durability and is favored.

Material and type

The materials of steel mesh are diverse, and different metal materials are usually selected according to the use environment and needs. Common materials are:

Low carbon steel plate: has good processing performance and toughness, moderate price, suitable for most ordinary occasions.

Stainless steel plate: has excellent corrosion resistance, suitable for wet, corrosive environment, such as chemical plants or Marine facilities.

Aluminum plate: Light weight, good corrosion resistance, suitable for high weight requirements, such as aviation and transportation industry.

Galvanized steel plate: the surface is plated with zinc layer, with strong anti-rust properties, suitable for outdoor environment.

According to the processing method and shape, the steel plate mesh can be divided into the following categories:

Ordinary steel mesh: hole shape is diamond, widely used in construction, Bridges and other fields.

Heavy steel mesh: larger thickness, higher strength, mainly used to carry large weight equipment platforms, protective screens and so on.

Microporous steel mesh: fine mesh, mainly used in filtration, protection and other precision applications.

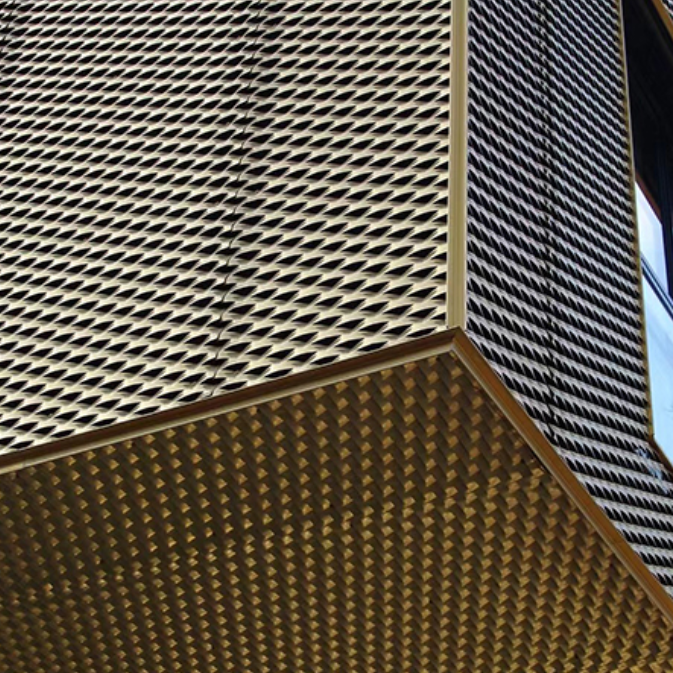

Decorative steel mesh: with beautiful surface design, often used in building exterior wall decoration, interior decoration and other occasions.

Manufacturing process

The manufacturing process of steel mesh mainly includes stamping, shearing and drawing three processes:

Stamping: The orderly stamping of holes in the steel plate through a die to form a grid structure.

Cutting: After the stamping is completed, the excess edge is removed by cutting equipment, so that the steel plate mesh is formed.

Drawing: The hole is stretched by the drawing process to form a diamond or other shape of the hole structure, and the mesh has a higher strength.

Product features

High strength, light weight: the steel plate mesh is made of a whole metal plate, there is no welding point, the structure is strong, the carrying capacity is strong, but at the same time, the weight is light, easy to install and transport.

Good ventilation: the mesh structure is conducive to air circulation, and is widely used in ventilation systems, equipment protection covers and other occasions that need ventilation.

Good anti-slip performance: the surface of the steel plate mesh is uneven, and has good anti-slip performance, which is suitable for foot pedals, walkways, platforms, etc.

Strong durability: After the use of galvanizing or spraying anti-corrosion treatment, the steel plate mesh can be used in a harsh environment for a long time and is not easy to rust or corrosion.

Application field

The application of steel mesh is very wide, the following are some main areas:

Construction industry: Used as building exterior wall, curtain wall, ceiling material, both beautiful and practical.

Safety protection: Used for workshop, warehouse, site safety protection fence, equipment isolation screen, etc., play a role in safety protection.

Equipment platform: Due to the anti-skid and high strength of the steel plate mesh, it is often used in equipment maintenance platforms and foot pedals in petroleum, chemical and other industries.

Decoration field: The hole shape of steel mesh is beautiful and diverse, and it is often used in interior decoration and furniture design, with a modern sense.

Customization and service

Steel mesh can be customized according to the specific needs of customers, including material, thickness, hole size, surface treatment and so on. Surface treatment methods are usually spray, hot dip galvanizing, oxidation treatment, etc., to meet the requirements of aesthetics and durability on different occasions.

Looking for the best Wire Mesh?

Schedule a Consultation

Get in touch with us now and book your appointment or get a free consultation for the issue you are facing.

Email:[email protected]

Phone/Whtsapp: +86 15933183030

Send Us A Message