Decorative Punching Mesh

Decorative Punching Mesh

Material: Color Punching Mesh

Certificate: SGS,ISO9001,IS014001,IS045001

Brand: SenZhe Mesh

Support: Standard products, customization

Origin: China

Product introduction

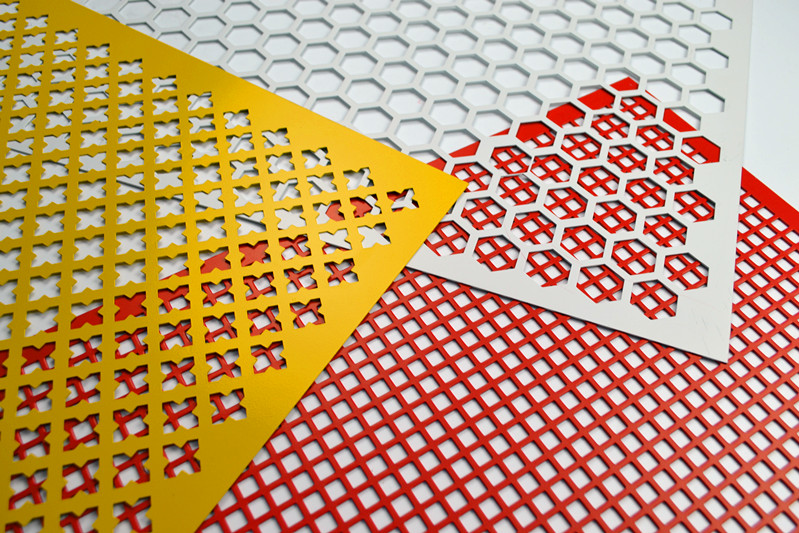

Color punching mesh is a metal screen product that is punched in the metal sheet by mechanical punching equipment and treated with color on the surface. It not only has a strong structural performance, but also can meet different decorative needs with a variety of colors, so it is widely used in architectural decoration, equipment protection, ventilation, screening, isolation and other fields. With its unique design, excellent corrosion resistance and beautiful appearance, color punching mesh has become the ideal material in modern architecture, industry and decoration. The following are detailed introductions from the aspects of material, structural design, application scenarios, installation and maintenance, and product advantages.

Material and surface treatment

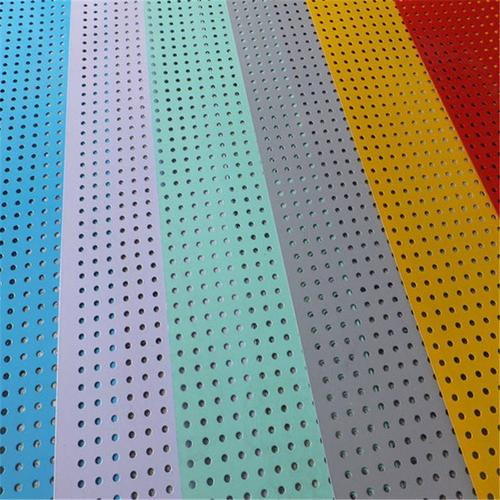

The commonly used materials of color punching mesh include stainless steel plate, aluminum plate, galvanized steel plate, cold rolled steel plate, copper plate and other metal materials. These materials not only give the punching mesh good mechanical strength, but also provide it with corrosion resistance and wear resistance. After the completion of punching, the color punching network usually carries out a variety of surface treatments, such as electrostatic spraying, anodizing, painting and so on. These surface treatments not only enhance the weatherability of the board, but also make it have a variety of color options, such as green, blue, red, white, etc., to meet the diverse needs of architectural decoration and industrial design.

Structural design

The color punching mesh is a regular or irregular punching process on the metal plate by high-precision mechanical equipment. The shape, size and arrangement of the holes can be customized according to specific needs, the most common hole shape is a round hole, but it can also be rushed out according to the decoration or functional needs of square holes, hexagonal holes, diamond holes and other special shapes. The aperture size ranges from 0.5mm to 200mm, the hole spacing and arrangement are flexible, and the plate thickness is optional from 0.3mm to 10mm. This structural design makes the color punching mesh have good ventilation, light transmission and filtering functions while maintaining a beautiful appearance.

Application scenario

Because of its diverse design and rich color choices, color punching mesh has a wide range of applications in many fields, the following are some typical application scenarios:

Architectural decoration: Color punching mesh is often used in exterior wall decoration, curtain wall, balcony guardrail, ceiling, indoor partition and other occasions, which is not only beautiful and generous, but also can increase the permeability and ventilation effect of the building.

Equipment protection: widely used in air conditioning cover, mechanical equipment protective cover and other occasions, can effectively protect equipment, prevent foreign matter from entering, while maintaining ventilation and heat dissipation effect.

Furniture and interior design: In furniture manufacturing, color punching mesh can be used for bookshelves, partitions, ventilation holes and decorative panels, which is practical and enhances the overall design sense.

Industrial screening and filtration: In agriculture, chemical, mining and other industries, for the screening and filtration of granular materials, to meet the needs of different particle sizes of materials, screening efficiency is high.

Transportation and public facilities: In public facilities such as subways, airports, bus stations, color punching mesh is often used in soundproof panels, protective barriers, fences and other facilities, which not only provides security protection functions, but also plays a decorative role.

Installation and maintenance

The installation of the color punching mesh is relatively simple and is usually installed by welding, bolted or special fasteners. Punching mesh can be cut and adjusted according to the actual scene, especially in architectural decoration, can be seamlessly connected with walls, ceilings and other materials. In equipment protection and public facilities, the installation of color punching mesh is also very convenient, and large area coverage can be quickly completed.

Due to the surface treatment of the color punching mesh, it has strong weather resistance and corrosion resistance, so the maintenance work is less. Under normal circumstances, it is only necessary to clean regularly to avoid the accumulation of dust and pollutants. Electrostatic sprayed or anodized surfaces are very wear-resistant and can retain their color and luster for a long time without additional protective treatment.

Looking for the best Wire Mesh?

Schedule a Consultation

Get in touch with us now and book your appointment or get a free consultation for the issue you are facing.

Email:Leoni@senzhemesh.com

Phone/Whtsapp: +86 15933183030

Send Us A Message